Would you believe us if we said that a large portion of nPhoto products, along with many of the components they are made from, are still hand-crafted in Europe? It’s true. While certain stages of production could be automated, we intentionally keep them in the hands of our skilled artisans. This allows us to ensure that every product is created with genuine care, precision, and respect for craftsmanship.

To give you a clearer picture, it takes several hours to create something as seemingly simple as an Album Box from start to finish. Depending on the selected options, more than a dozen people may be involved in its creation. Each product is manufactured by us in our European facility, with only essential raw materials, such as cover fabrics, sourced externally. Many of our other products follow a very similar path, but we will return to those shortly.

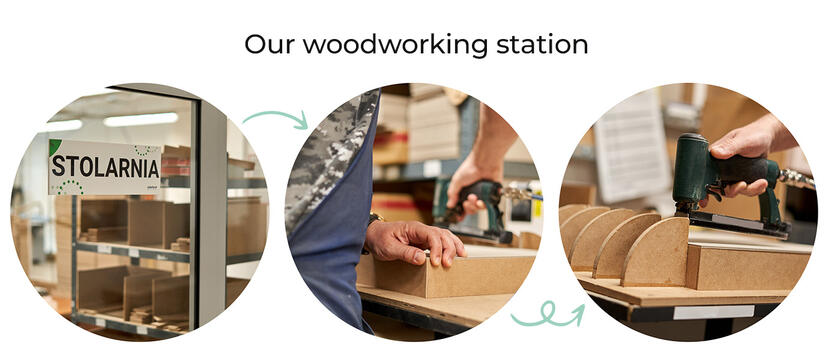

Every box begins its journey in the woodworking section of our production facility. That is no exaggeration. To ensure consistent access to materials and maintain full control over quality, we operate our own professional woodworking station. This is where precise measurements are taken, box bases are constructed, and where the foundations of many other products are formed, including Wall Decor frames and backboards. If you assumed our boxes were supplied by an external manufacturer, this may come as a surprise. In reality, they perfectly reflect what it means to be hand-made, even when produced on a carefully managed, larger scale.

Attention to Detail and Precision

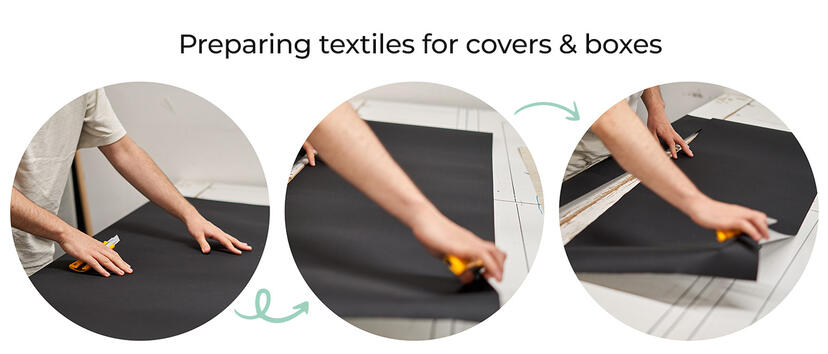

As the process continues, once the wooden framework is complete, each box is carefully finished with one of our cover materials. This stage also relies entirely on skilled hands rather than machine automation. In our European production facility, rolls of textile, leatherette, and velvet are selected, measured, and cut to the exact size required for each box. These precisely prepared pieces are then carefully fitted, pressed, and attached to the wooden frame by hand. This meticulous approach ensures a flawless finish and reflects the level of precision and attention to detail that defines our craftsmanship.

It goes without saying that every stage of this process demands exceptional care and precision. Fabrics and adhesives are a particularly demanding combination, which is why each step requires thoughtful coordination and experienced hands. From material handling to timing, every detail is planned to ensure consistency and quality throughout production.

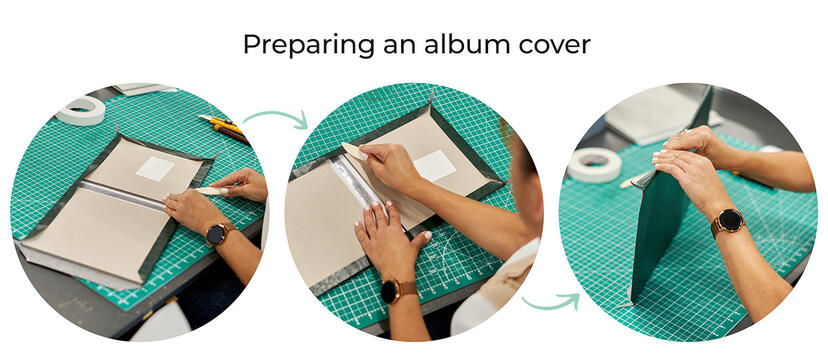

Take one of our boxes, or an eco-leather album with stitched details, as an example. Before the final product can take shape, each individual element must first be prepared according to its selected personalisation options and add-ons. If an album is ordered with names and a wedding date on the cover, that cover is carefully passed to our textile specialists. There, the text is applied using a press, letter by letter, with precise spacing measured and checked before the cover is approved. Only then is it combined with the remaining elements of the product. This careful, hands-on approach ensures that every personalised detail meets the highest standards of European craftsmanship.

Introducing elements such as seams requires the same level of dedication and skill. Our experienced tailors work with professional sewing machines, carefully visualising the final result at every stage to avoid even the smallest imperfection. Other detailed add-ons that enhance our products are also completed by hand, ensuring consistency and a refined finish.

Our USB pendrives follow a similarly thoughtful process. Each one begins with the selection of materials that match the box it belongs to, after which both the interior and exterior are carefully assembled using hand tools. Even the smallest details matter here, including ribbons that are individually cut and tied by hand.

Behind every product are people who are passionate about what they do

Nearly every Box, Photo Album, and Photo Book collection features a cover created by skilled people rather than automated systems. It is our production team who prepare fittings for acrylic covers, cut materials to size, and tie ribbons onto USB pendrives. These products can truly be considered handmade. While the print itself is produced using modern technology, everything that surrounds it, from frames and edges to adhesives and final assembly, is carefully crafted and brought together by our European artisans into one cohesive product.

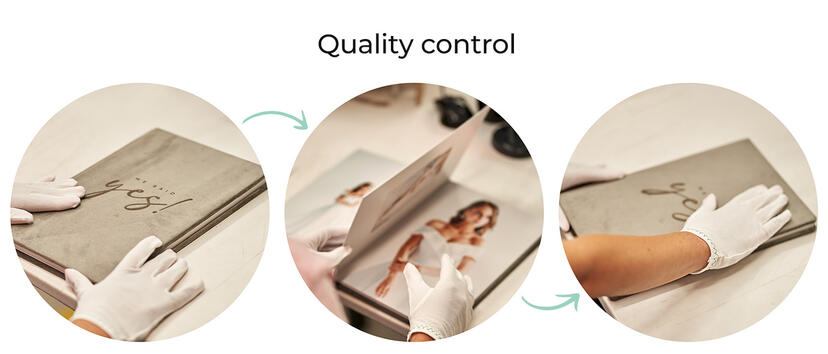

The final packaging stage, handled by its dedicated department, is also largely a manual process. Orders that include multiple products are carefully assembled, secured, and placed into protective packaging before being sealed and prepared for delivery. At a production scale like ours, maintaining consistently high standards is essential. This is where our dedicated quality control team plays a vital role. Every order is carefully inspected and verified, ensuring that only products which meet our strict quality requirements leave our European facility.

Color correction professionals truly appreciate

Color correction has been an integral part of our lab since its very beginning, with experienced specialists overseeing this stage from day one. While only a handful of labs offer this level of service, we have refined it into a smooth and reliable process through the support of advanced technology, always guided by human expertise. It is this balance of innovation and skilled craftsmanship that ensures every print meets the expectations of professional photographers.

Necessity is the mother of invention

Many of our newer product lines are the result of in-depth research into the real needs of photographers. One such example is the Accordion Mini Book, which was met with great enthusiasm upon release. From the very beginning, it was designed to reflect the character of a hand-crafted product. Achieving this required testing and refining unconventional production methods so it could still be created by hand, even at a larger European production scale.

These unconventional approaches were present even in the earliest days of our lab. When we were just starting out, embossing was done using clothing irons, and kitchen ovens played a role in our production process. Looking back, these beginnings highlight just how far we have come. Yet one principle has never changed. Our products are still made by people. Human hands remain at the heart of our production, and they have never been fully replaced by machines.

Exceptionally unique products your clients will want to experience

You and your clients can see this craftsmanship firsthand through our current sample offer. Receive 85% off a sample Photo Album and Complete Album Set, along with a pack of Retro Prints, for just 1 USD, EUR, or GBP. Use the button below to learn more and start offering products that truly reflect the quality and care behind your work.

Photography is art

To us, this has always been self-evident. Art deserves the right medium to elevate it and allow it to be experienced at its fullest. We believe our handcrafted products can become that medium for your work. Allow us to bring the same passion, care, and craftsmanship shown throughout our production process into every future order you place with us.